PVC and the Environment

Sustainability, environmental impact and carbon footprints continue to be hot topics in every industry – and rightly so. Companies and consumers alike are putting more focus on going ‘green’ when it comes to products being manufactured, used, re-used and then ideally recycled into something new.

Some of this debate around the environment has shone a spotlight on PVC. While there is certainly room for improvement, this material remains the best option for properties when it comes to both use and recyclability. It’s a reliable option, and PVC can actually reduce energy usage and CO2 emissions during its lifespan, and afterwards.

Versatile and cost-effective, PVC is the most important polymer in the motorhome, construction and fenestration sectors. In this article, we’ll take you through some of the ways we’re working with PVC and what its recyclability means for plastic extrusions specifically.

Recycled Materials in Plastic Extrusion Products

As the needs of the customers change, so do the ways companies work. In fact, that’s exactly what we here at Rocal Extrusions and within the wider Rocal Group are expressing and working towards. In our own words:

“Our mission is to engage efficiently and responsibly in all areas and to participate in the development of new products to meet evolving customer needs. Rocal seeks to ensure we produce and deliver to our customers in an environmentally and socially responsible way.”

But our commitment to using recycled materials within our extruded profiles is more than just words. We’re actively striving towards a greener future with our products, services and operations to push recycling in our plastic extrusions.

On a wider level beyond just Rocal Extrusions, there is plenty of debate around the benefits and potential drawbacks of using recycled materials in the process.

Advantages:

Environmental Impact & Carbon Footprint – More recycling means less waste, which cuts carbon emissions and helps to save the environment. This is important on all sorts of scales; it matters to the people in the factories, the customers at home, and the world as a whole.

Cost-Effectiveness – Recycled materials can be a more cost-effective option, and transparent companies should pass these savings on to the consumer and end-user, which helps when the cost of living crisis is as much a talking point as the environmental one.

Compliance – Recycling and sustainability is a talking point for more than just consumers. Governing bodies are putting regulations into place around environmental impact, so manufacturers must change their practices to work in a more compliant way.

Disadvantages:

Quality Concern – Performance is, of course, a key factor in any product, so it’s important to be aware of concerns that impurities and inconsistencies in the recycled raw materials can affect the performance of the final extruded component.

Increased Processing Costs – While there are some savings to be made with recycled profiles, there can be additional expenses incurred. For example, to ensure the best quality and performance, materials may have to be rechipped before they can be processed in an extruder again. This extra step can mean extra costs, and while this is offset somewhat by the positive environmental effects, money is naturally an important consideration for people and companies too.

TimbPlas is Recyclable

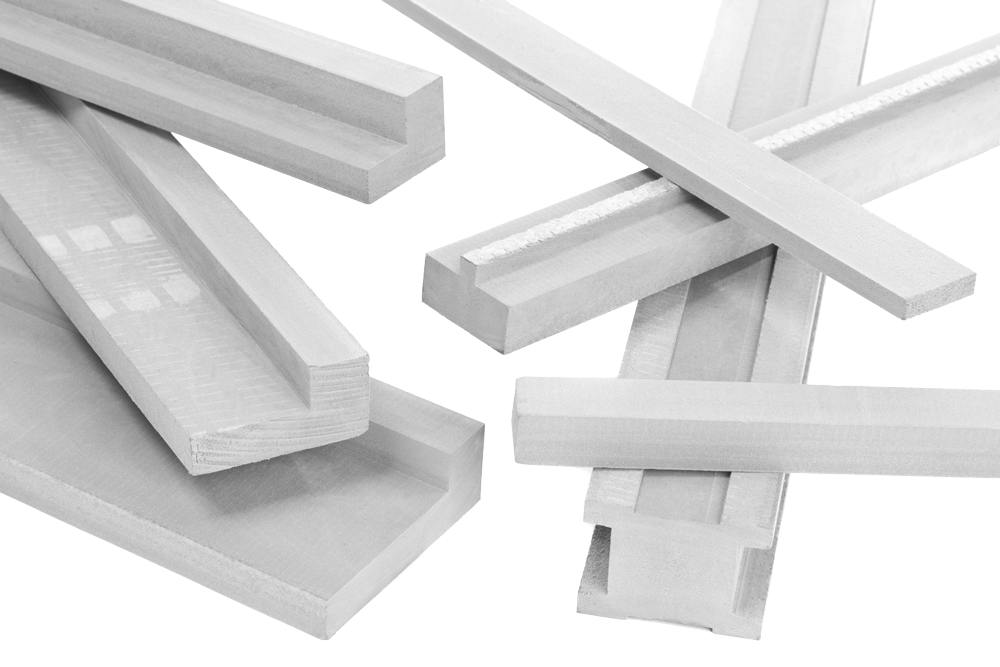

In light of these perceived advantages and disadvantages, what are we here at Rocal Extrusions contributing to the sustainability and environmental awareness drive? That’s where our innovative TimbPlas comes in.

Not only can TimbPlas be manufactured using recycled material, but it can also be recycled itself at the end of its use. Unlike natural timber, this polymer material will also outlast any product in which it is used.

TimbPlas offers a similar U-Value performance to softwood of the equivalent thickness. Replacing your existing timber structure with this polymer material means no increase in heat loss and no thermal bridging.

If you’re interested in finding out more about our climate pledge – or to enquire about our Timbplas product – we welcome you to get in touch with our team online or by phone at 01652 225 200. We’ll be happy to answer any questions you may have.