Rigid Plastic Extrusions

We manufacture rigid plastic profiles in a wide variety of different shapes, colours and finishes to meet the desired specification and application of each of our valued customers.

According to your specification and dependent on its application, we can extrude rigid plastic profiles with thermal properties, flame retardancy, impact strength and both UV and chemical resistance.

We manufacture rigid plastic profiles in a wide variety of different shapes, colours and finishes to meet the desired specification and application of each of our valued customers.

According to your specification and dependent on its application, we can extrude rigid plastic profiles with thermal properties, flame retardancy, impact strength and both UV and chemical resistance.

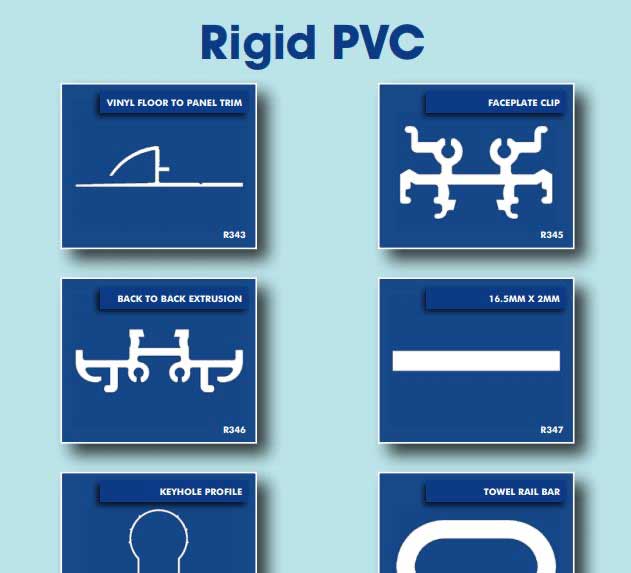

STANDARD

RIGID PLASTIC

EXTRUSIONS

In over a decade of manufacturing rigid plastic extrusions, we have developed tooling for well over 300 different profiles. From simple T-sections to more intricate rebated profiles, our bank of standard rigid plastic profiles may include the perfect profile to fulfil your requirements.

View our list of standard rigid plastic extrusion profiles to see if we already stock your desired profile for a fast, cost effective solution to our needs.

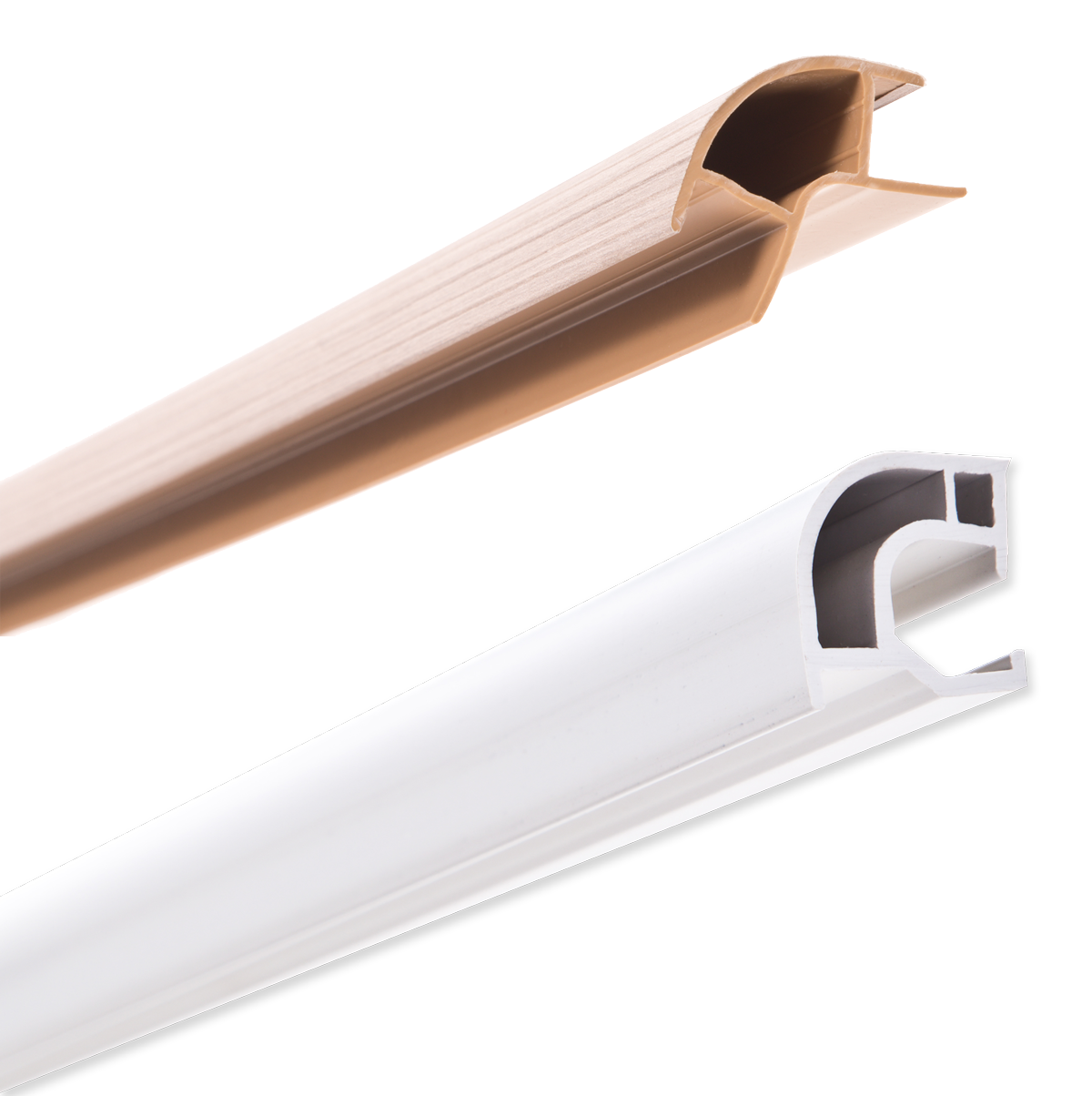

BESPOKE

RIGID PLASTIC EXTRUSIONS

Thanks to our in-house tooling expertise, Rocal Extrusions can quickly and cost effectively design, develop and manufacture bespoke rigid plastic extrusion profiles to perfectly suit your chosen application.

Once our knowledgeable understand your requirements, we can advise you on the correct material, specification and design to ensure your bespoke rigid plastic extrusions exceeds your expectations.

RIGID PLASTIC

PROFILE PRICES

Our on-site plastic extrusion and secondary operation machinery allow us to offer faster lead times and carry out cohesive projects by the same team of experts. The time and money we save us then passed on to you, meaning we are proudly able to offer more cost-effective plastic extrusions and superior quality profiles for you, whatever your needs may be.

To request a quote for one of our standard rigid plastic profiles, or a price for a bespoke requirement, use the link below.

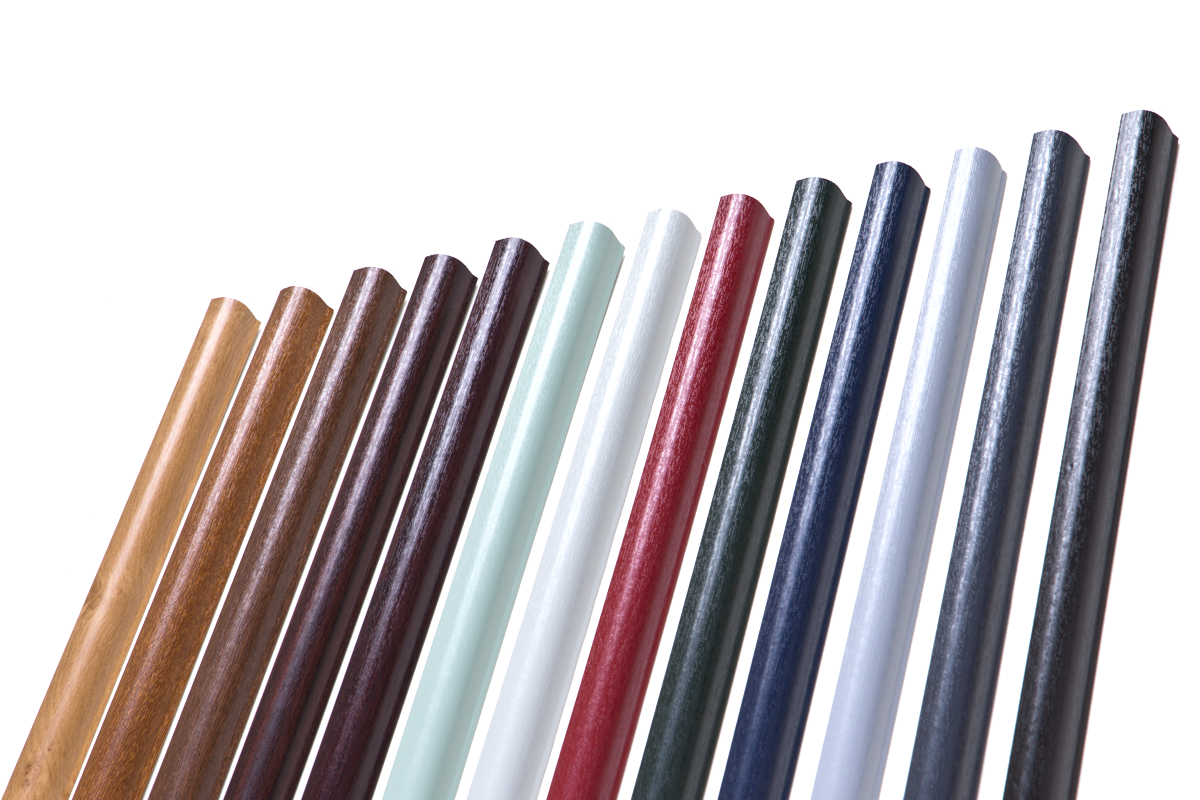

FOIL WRAPPED RIGID

PLASTIC EXTRUSIONS

Adding the finishing touches to your rigid plastic profile is easy with Rocal Extrusions. Not only are we able to blend our polymers to offer a colour match to any pantone colour, we also offer both on-line and off-line wrapping services.

We stock a wide range of foils and papers, from realistic woodgrain finishes to bold colours and even metallic effects too, offering you an impressive choice of finishes as standard.

If you’re looking for a perfect match between your desired plastic extrusion and your existing product, we are able to source the required papers or foiling to meet your required specification.

HOW DO WE MAKE

RIGID PLASTIC EXTRUSIONS?

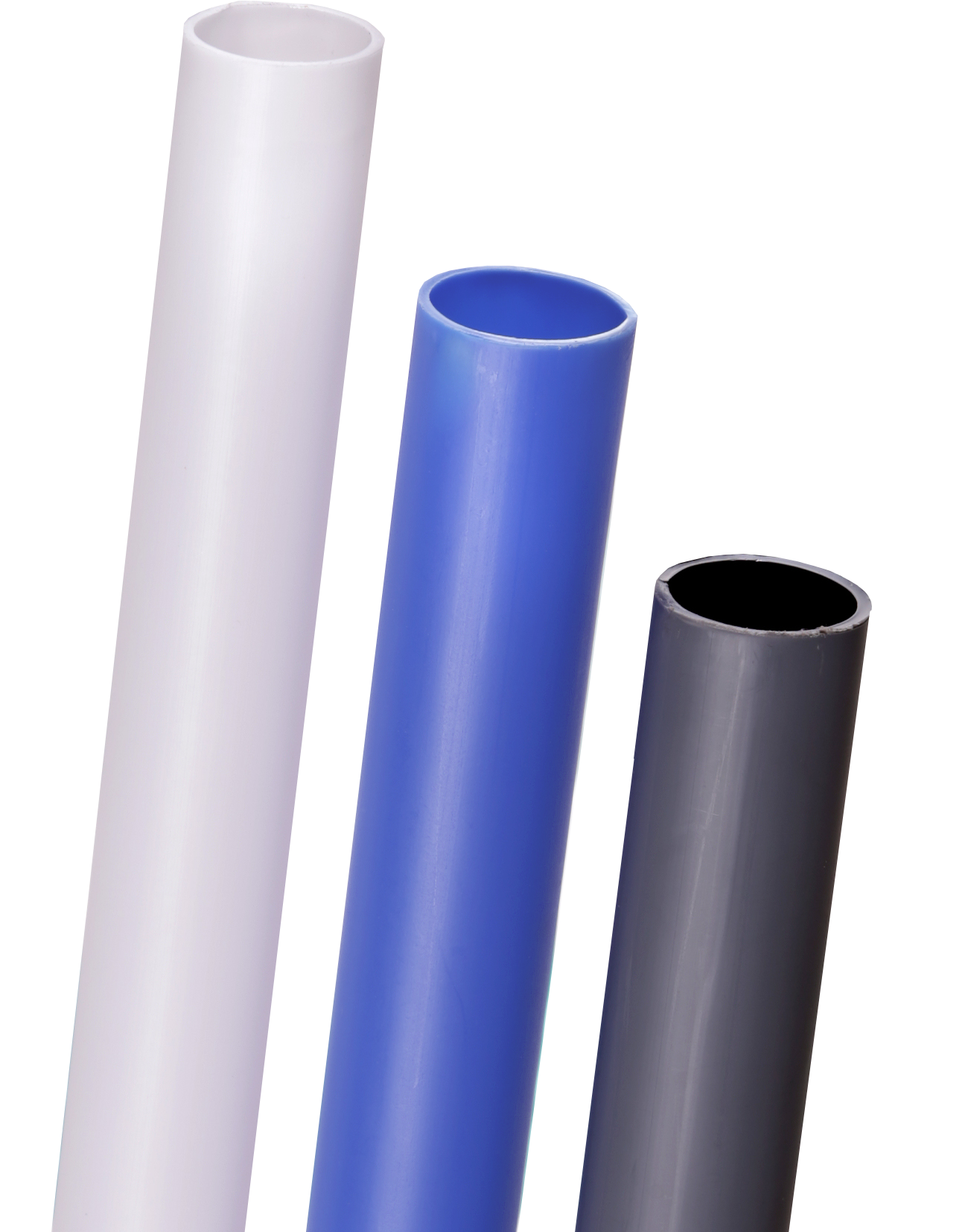

Either PVC or ABS granules are fed into the hopper of our extrusion machines and are then drawn down into the screw. The screw is then heated by external heating elements, causing the polymer granules to melt and become more malleable. As the polymer granules move along the screw, they are forced though a die, containing the cross section of the profile of the extrusion required. The profile is then fed through a series of cooled water baths before being cut to size and packed.

Downloads

COMPANY

PRESENTATION

Promotional presentation for Rocal Extrusions with information about our company and services.

TIMBPLAS

PRESENTATION

Promotional presentation for the TimbPlas product including USPs and Case Studies.