We are proud to introduce our exclusive RocFoam technology: a result of our 13 years of experience in plastic extrusions and composite doors. Our innovative RocFoam is a unique direct replacement for timber. This vinyl based cellular thermoplastic extrusion has been developed by us at Rocal for a variety of different uses and applications within many industries. RocFoam can be used to replace timber, offering most of the same advantages without any weaknesses.

RocFoam offers many technical benefits. It is extremely lightweight where timber is not and is also completely moisture resistant. It will not expand when exposed to water in any situation, even in the most adverse weather conditions. Moreover, it is also entirely resistant to changes in temperature and does not rot. RocFoam is also highly customisable and can easily be painted. It offers a good screw fixing and has good adhesion to a wide range of surfaces. All in all, this innovative creation is extremely versatile and offers modern performance benefits that other commonly used natural materials do not.

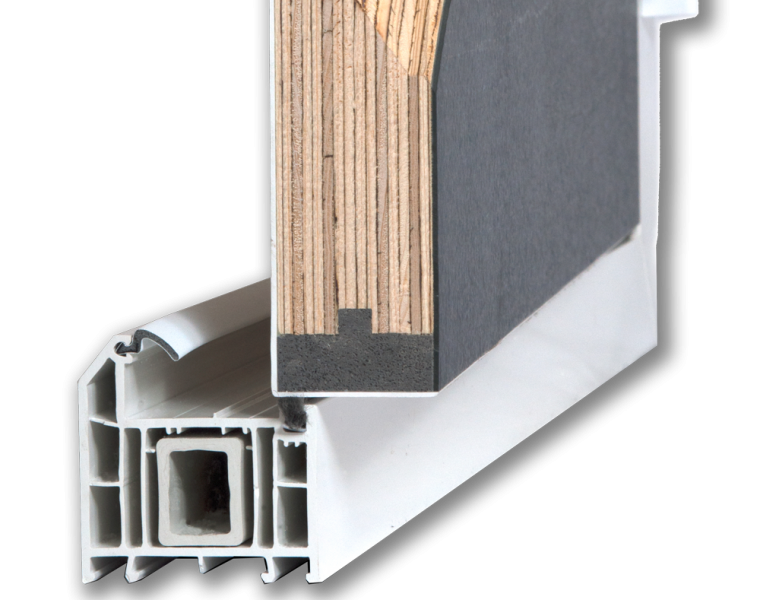

Here at Rocal Group, we now use RocFoam in all of our composite doors, as well as in our moisture resistant internal doors. This is due to it being the perfect material for robust front doors: it is lightweight while also expansion and moisture resistant. Endurance Doors, who are part of the Rocal Group, is now a firm favourite for composite doors in the UK. Rocal composite doors have a modern yet unique design system. They feature a solid timber core, high security features and a customisable design that is bespoke to each specific customer. RocFoam is internally fitted at the base of the Rocal composite doors and moisture resistant internal doors to provide further protection and reinforcing. These key features are just a few of the many unique attributes of our moisture resistant doors.

Their extensive use has led them to become in high demand with the public and trade within the housing industry. RocFoam is quickly replacing timber as the main material within fixtures and frames for Rocal composite doors and moisture resistant internal doors.

RocFoam can be manufactured in customised rebated profiles and in house dies to create bespoke profiles to meet the needs of your business. It can also be manufactured to meet specific weight requirements for whatever it is you need, whether that be moisture resistant internal doors or something completely different.

If you would like to find out more about RocFoam and how it can be incorporated into your products, please contact us today. If you are interested in our state of the art Rocal composite doors, please visit either our Rocal site or our Endurance Doors site.

If you have any questions you would like to ask us directly, please do not hesitate to call us on 01652 228466.