From standard plastic tubing used in manufacturing to everyday household items, products created by plastic extruders are all around us. What is less common is understanding the process behind these products and the machinery the plastic extruder machine that makes them.

For those who focus on the end products, it’s easy to overlook the intricate plastic extrusion process. However, understanding how a plastic extruder works helps to appreciate the benefits of working with a trusted manufacturer like Rocal Extrusions.

Even though the machinery may look complex, the actual process of extruding plastic is relatively straightforward. Below, we explain how plastic extruder machines work and why they are essential in producing high-quality plastic products.

How Do Plastic Extruder Machines Work?

At its core, a plastic extruder turns raw plastic materials into finished products through a simple process: raw materials go in, extruded plastic products come out. However, there are key technical details that ensure efficiency and quality.

At one end of the plastic extruder machine, called the hopper, raw resin and other additives are fed in. The material then moves along a heated barrel via rotating screws, gradually melting under high pressure.

This thermoplastic extrusion process ensures consistent quality and prevents degradation of the plastic, a key advantage of using high-performance plastic extruder machines.

Advanced plastic extruder machines include safeguards and systems to control melting and maintain uniformity, ensuring the final product meets precise specifications.

Quality & Consistency in Plastic Extrusion

The plastic extrusion process may seem simple, but quality relies on precise internal controls.

- Temperature control is crucial: overheating can degrade plastic, while too low a temperature can prevent proper extrusion.

- Screw design is another critical factor: the length, diameter, and pitch of the screws in a plastic extruder machine are carefully engineered to match the type of raw material and ensure consistent melting rates.

These elements guarantee uniformity in plastic profiles, sheets, and other extruded products, giving manufacturers reliable results for every batch.

Speciality Plastic Extruder Machines

Not all plastic products are simple. For complex or multi-layered profiles, specialized plastic extrusion machinery is required.

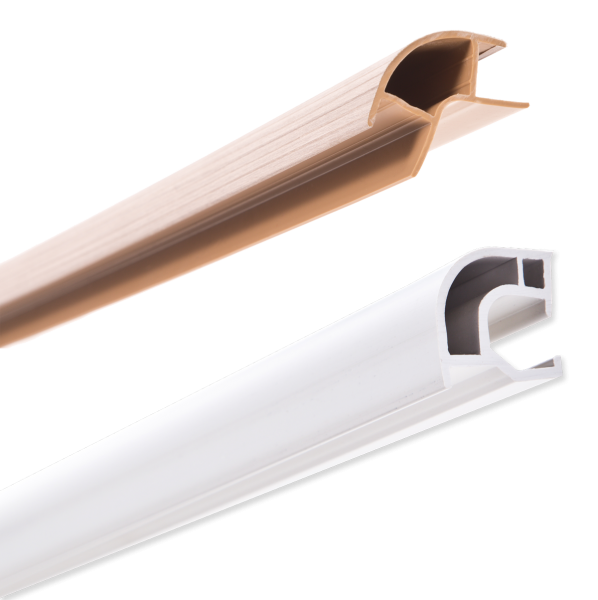

One advanced technique is co-extrusion, where multiple layers of plastic are extruded simultaneously. Multiple plastic extruders feed different types of plastic into a single product, enabling custom layering for added strength, colour, or functionality.

Rocal Extrusions specialises in co-extruded plastic profiles, offering precision and quality that many standard extrusion manufacturers cannot achieve.

Sourcing Plastic Extrusion Machinery

While the products they produce are commonplace, plastic extrusion machinery itself isn't easy to come by. For machines that give the best results and extrude the products you need, you'll want to look to the experts.

Plastic extrusion machinery at Rocal Extrusions has been developed and refined with customers' needs in mind and is expertly used to create what you need.

Talk to our team about the plastic extrusion machinery we offer to confirm that it's the right fit for you. With standard and more bespoke profiles available for a wide range of sectors and industries, we're sure to have what you need.

The Right Plastic Extrusion Machine

If you’re in need of extruding plastic and need high quality products at competitive prices, make sure you choose the right manufacturer with the specialist plastic extrusion machinery.

Here at Rocal Extrusions, we’re a leading plastic extruder machine specialist because of our advanced technical plastic extrusion machines – with the experience and knowledge to use them to their fullest potential.

Not all plastic extrusion machines are made equal, and not all of them are able to get the job done with the standards and specifications that you require. Whether you’re looking for standard plastic profiles or more complex co-extruded extruded plastic, our machinery is able to create what you need.

What’s more, with our custom tooling on-site, our extrusion machines go further than most. We’re able to customise your plastic profiles with a wide range of colours and finishes as well as various wrapping options.

Choose our plastic extrusion experts with our professionally operated extrusion machines when extruding plastic. For all your needs, you can rely on Rocal Extrusions.