Since being established in 2009, Rocal Extrusions has gone from strength to strength, becoming one of the key players in the extrusions industry with market-leading profiles and products.

Rocal was originally established in 1993 as a manufacturer of door panels. Rocal Extrusions was born from this to manufacture a variety of plastic extrusions for a range of different industries, purposes and uses.

Over the past 9 years, Rocal Extrusions has evolved and no longer only manufactures plastic extrusions but also provides custom tooling alongside a range of finishes, colours, wrapping and secondary operations.

The uses of plastic extrusions are endless, and many of the products we manufacture are used day in day out in everyday life.

How Have Rocal Extrusions Evolved?

In 2009 we started up with just one plastic extrusion line. Product development has always been and will continue to be a key element of our expansion.We chose not to rely on standard profiles and products but instead expanded to have a production unit which now holds 9 plastic extrusion lines and a tool making department.We are one of the only plastic extrusion manufacturers in the UK to offer wrapping and foiling services. We have also developed our own unique timber replacement material RocFoam.

After years of development and testing, RocFoam is a direct replacement for timber which has exceptional features and benefits. It is lightweight and moisture and temperature resistant, making it a durable and long-lasting solution.

We have invested time, money and resources into our workforce and machinery to get to where we are today.

What Plastic Extrusions do Rocal Extrusions Provide?

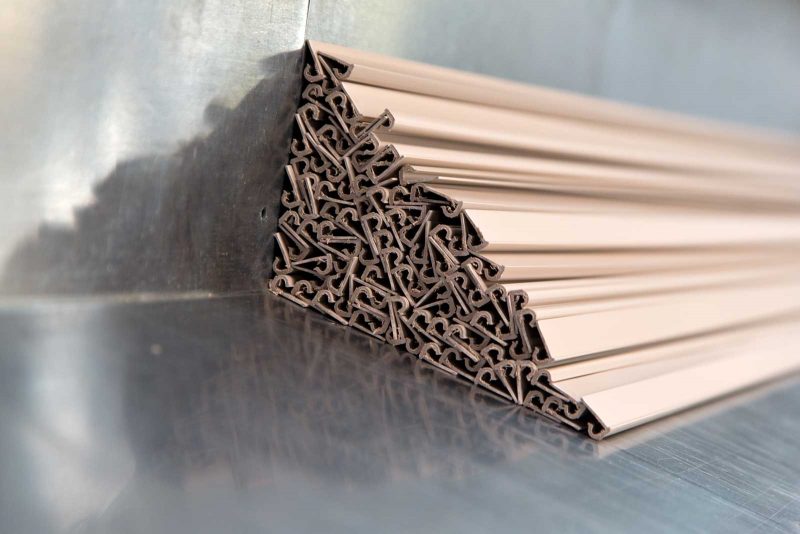

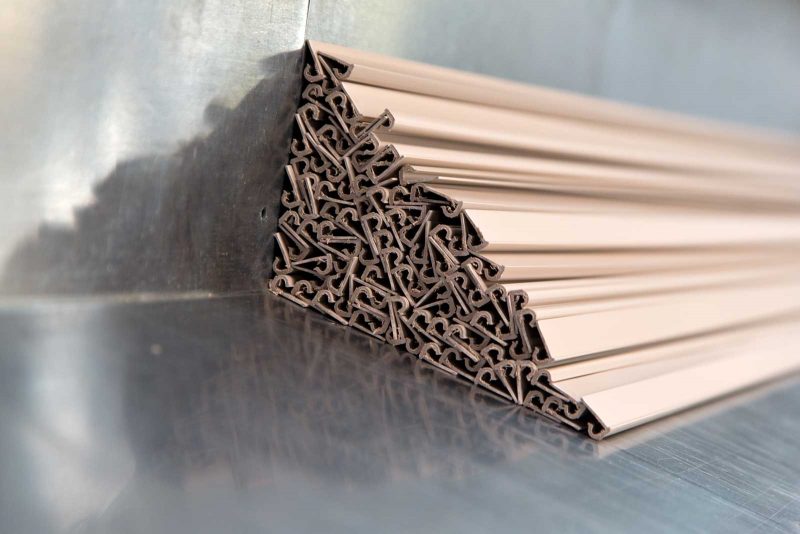

We can supply a range of standard plastic extrusion products as well as a bespoke design service depending on your project needs.Our experienced team use the latest CAD software to assist with product design and polymer choice. As well as this we’re able to create prototypes using 3D printing to ensure the product is exactly as you wish.

From flexible plastic extrusions, rigid plastic extrusions, co extruded plastic profiles and standard plastic profiles… our products are the perfect addition to your project.

We also provide extrusion services such as finishes, colours, wrapping, secondary operations and custom tooling.

What is Rocal Extrusions’ Mission?

Our mission is to continue to develop and perfect products to meet evolving customer needs. We work to ensure that we produce and deliver in a profitable and environmentally responsible way. We work closely with our customers and partners unlike standard suppliers, to truly understand their need and uses of our plastic extrusions. We develop ways to make the production easier, either by assisting with shape or adding a process that reduces production time. Our mission is to continue to develop and perfect our services to maintain our position as one of the key players in the plastic extrusions industry.Why Should you Choose Rocal Extrusions?

Due to the flexibility we’re able to provide on orders and production, we can undertake any size project, big or small. We have short and long batch runs available, making us the perfect choice for getting your project completed on time and in budget.Our own fleet of vans and lorries are used to transport your order to you, with a quick and efficient service and fast lead times.

We have our own custom tooling facility with excellent facilities. From rough sketches to using CAD drawings, the end result is a plastic extrusion that is unique and reliable.

We can wrap your plastic extrusions to match your project with a selection of vinyl’s and foils. Our service is bespoke made to your needs.

We also work closely with our PVC supplier to ensure you get the exact colour you want. We can also provide clear or frosted PVC depending on your needs.

We also have a 3D printer to create prototypes which means that you can check the design, shape and size before manufacture. This makes our service a lot more efficient and means that we can get your design on the production line a lot quicker than most of our competitors.

We have over 30 years’ experience with a wealth of knowledge of thermoplastic extrusions. We have drawn on this knowledge and experience to develop some of the most useful extruder profiles on the market.

Get a Quote for your Plastic Extrusions

If you have a strong idea on what you are looking for and would like to obtain a price for your plastic extrusions, send us your drawing and we can provide a quote within 24 hours.If you’d like to discuss your plastic extrusions requirements and take advantage of our expert advice and recommendations, you can call us on: 01652 659259.

Whether you know exactly what kind of profile you require, or you need a little guidance, our technical engineers are more than happy to offer their advice on the right extrusion for whatever the application.