Sometimes, a bespoke plastic extrusion isn’t required, which is why at Rocal Extrusions we produce a wide range of standard plastic profiles that are ready to order.

Over the past decade and more, we’ve evolved and now provide a range of

finishes,

colours,

wrapping and

secondary operations.

Our

custom tooling options are impressive and extensive, but we understand they are not always required. Sometimes a standard profile will do the job more effectively.

We have the tooling available to produce a variety of

standard plastic profiles, meaning that we’re able to turn an order around quicker than many of our competitors.

By choosing Rocal, your project will be handled wholly by our team at part of our comprehensive service. This means that not only do you benefit from faster lead times and a more cost-effective service, since we complete it all on-site and never outsource, but you'll also enjoy our expertise all through the process.

This is particularly beneficial if you’re looking for a company that you can rely on and trust to get your plastic extrusions to you on time and in budget.

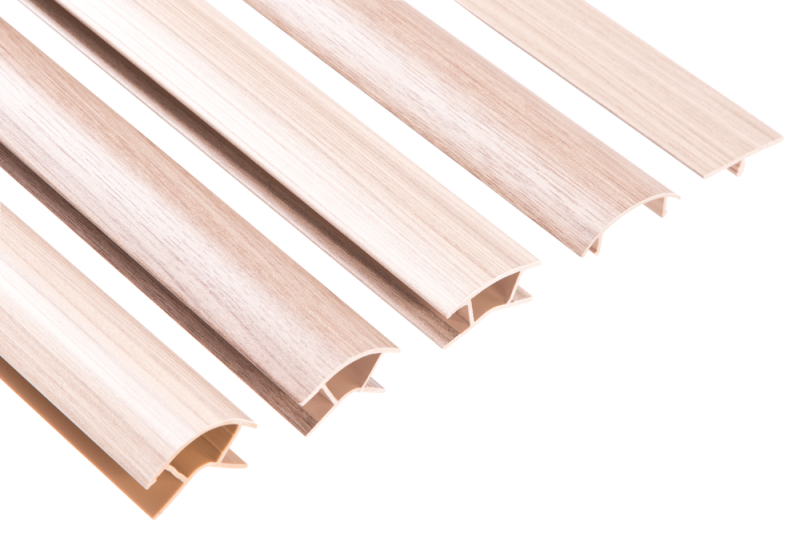

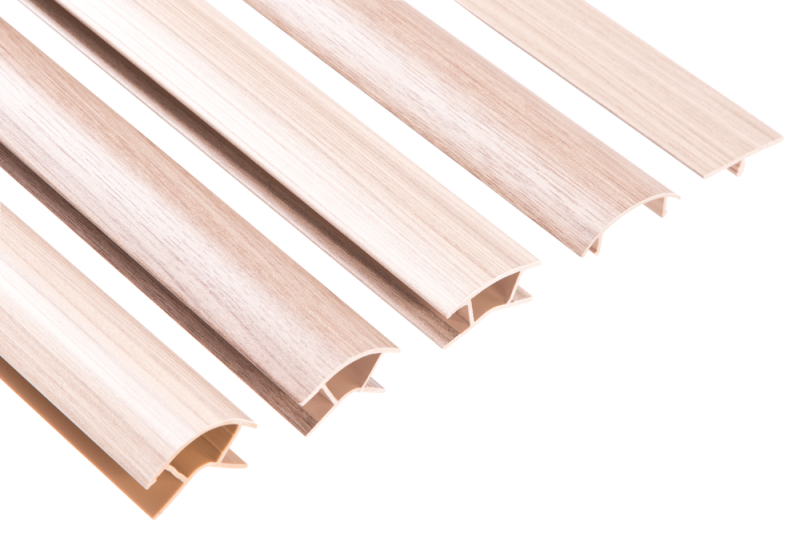

A Selection of Rocal's Standard Plastic Extrusion Profiles

| Corners |

J Sections |

| Angles |

Cornice |

| H-Sections |

Capping |

| T-Trims |

H Sections |

| 15mm flat strips |

18mm flat strips |

| 35mm flat strips |

38mm flat strips |

| ABS Capping |

Corner Moulds |

| Skirting |

Various sizes of tubing |

| 50x50mm internal and external angles |

15x15mm angles |

| Various sized T-Part tops and bottoms |

Various sized T-Trims (or Knock-in-Ts) |

Rigid and Flexible Plastic Extrusion Profiles

We have all standard profiles ready to order, with a quick lead time and lots of colour to choose from. You aren’t limited to plain white at Rocal.

You can define your standard profile with colour, a vinyl-wrapped finish or foil depending on your particular needs and requirements.

Standard profiles are ready for you to order, and with our expert team on hand, we can even adjust these to give you a unique twist for the end product.

With both rigid and flexible plastic extrusion profiles available too, you can find the right fit for what you need.

Our extensive range of tooling exceeds 500 profiles and alongside the facilities to allow us to design and manufacture your own, you can trust in placing your order with us.

We'll complete every aspect of your project on-site. We don't need to outsource, which means you'll benefit from our commitment and experience throughout.

Our standard plastic profiles are dependable and will do their job well - we understand the importance of that above all else.

When you choose Rocal you are selecting quality, reliability and durability.

Flexible Plastic Extrusions

Our

flexible plastic extrusions and tubes can be made from a variety of material types including TPV, TPE and Polyurethane.

We can offer advice on which material is best to use for your project or needs.

Our technical engineers are happy to discuss your requirements and recommend the best possible solution for your needs and requirements.

We have a wealth of experience and knowledge that we draw upon for each project that we undertake and we’re happy to advise on each step of the process.

Rigid Plastic Extrusions

Our

rigid plastic extrusions are produced to a high quality and will always meet your specification and expectations.

Select your material and colour to enjoy rigid plastic extrusions that are quality in design and finish.

We can also extrude rigid plastic profiles with thermal properties including flame retardancy, impact strength and both UV and chemical resistance.

Simply let us know what rigid plastic extrusions you require and we can help fulfil your need and requirements.

Why Choose our Standard Plastic Extrusions?

In modern buildings, it is difficult to find a room without one or more plastic extrusions, which is why we have standard profiles to meet your everyday needs.

We’ve designed profiles for numerous industries, including automotive, leisure homes, windows and doors and cladding.

Plastic extrusions are an integral component in a lot of industries, which is why we ensure that each plastic extrusion we create is capable of meeting the needs of the project.

Due to its lightweight composite, versatility and cost-effectiveness, plastic is the ideal material for many uses and there are many types.

Most sectors depend on plastic, including construction, manufacturing, refurbishment, interior design and more.

Profiles can be manufactured to required lengths as part of the production process.

We also manufacture co-extrusions which is a combination of rigid and flexible materials. A flexible middle membrane can be joined to rigid parts to allow for slight movement.

Get A Quote for your Plastic Extrusions

If you have a sure idea of what you’re looking for and need a price for our standard plastic extrusions simply

get in touch today.

Speak to us about your needs and we can determine whether you require a custom extrusion. It may be that one of our stock extrusions will meet your needs thereby being more cost-effective and minimising time in production.

We provide a seamless service from design, in-house tooling, through to production and delivery.

Extrusion is an economical manufacturing option as it is a highly efficient process and there is minimal material waste.

Our expertise in manufacturing plastic extrusions is built upon many years of experience and the company works as a team to ensure that our products and services are of the highest quality.