At Rocal Extrusions, we’ve got all your extrusion needs covered — from standard profiles to flexible or rigid solutions, we offer a wide range tailored to meet your business requirements.

One of the most versatile options we provide is extruded tubing, ideal for applications that require durable, adaptable, and precisely engineered plastic tubes. Join us as we discuss everything you need to know about extruded tubing.

What is extruded tubing?

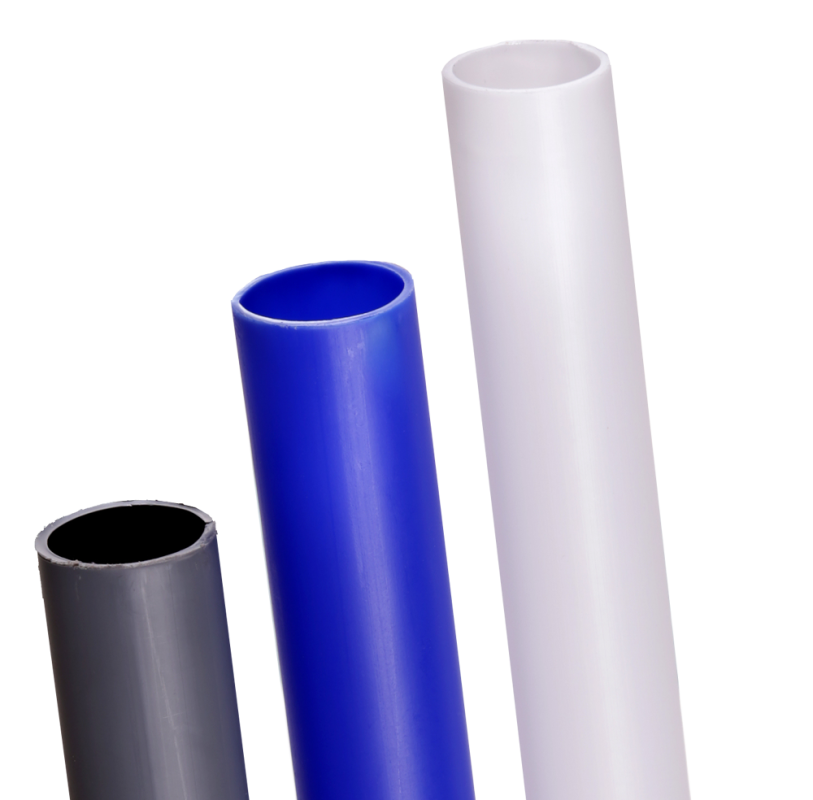

Extruded tubing is a manufacturing process where plastic tube profiles are produced to meet precise customer specifications. These tubes have a wide range of applications across various industries, and many businesses choose to outsource production to us due to the simplicity, reliability, and efficiency of our service.

At Rocal Extrusions, we use high-quality materials such as PVC, Polypropylene, and ABS to create both rigid and flexible tubing. Each product can be fully customised to meet specific requirements — from temperature resistance to food-grade compliance.

With extensive experience in producing round plastic tubes and rods, we support a broad spectrum of industries and applications. We also offer plastic box sections, known for their excellent strength-to-weight ratio and versatility. These are available in a range of sizes and wall thicknesses to suit your exact needs.

How is tubing made?

At Rocal Extrusions, we manufacture plastic tubing in diameters ranging from 8mm to 75mm, with a wide variety of wall thicknesses to suit your exact requirements.

We offer tubing in high-quality materials such as PVC, Polypropylene, and ABS, each chosen based on the application and performance needs. These materials are heated, shaped, and formed into your desired tube profile using precision tooling, then carefully cooled to ensure consistent, high-quality results.

While we don’t stock plastic tubing off the shelf, we maintain an extensive range of ready-made tooling, enabling us to produce both standard and custom profiles quickly and cost-effectively. Whether you're after flexibility, rigidity, temperature resistance, or specific colour options, our team will guide you in selecting the right polymer blend for optimal performance.

If one of our standard profiles suits your needs, we can get started right away. But if your project requires something more specific, we also offer bespoke plastic tube extrusions — tailored solutions designed and manufactured to meet your unique specifications.

Unlike other plastic tubing extrusion companies, our in-house custom tooling capability allows us to develop bespoke tools that are specifically designed to produce your profiles without the need to outsource, saving our customers both time and money.

Where are extruded plastic tubes used?

Thanks to the versatility of our manufacturing capabilities, Rocal’s plastic tube extrusions are used across a wide range of industries and applications. From everyday products like bird feeders and household items to more specialised environments such as medical testing facilities, our flexible and rigid tubing serves both simple and highly technical purposes.

Whether you need a standard tube or a fully bespoke solution, Rocal Extrusions is your trusted partner for high-quality plastic tubing. With in-house tooling, material expertise, and a customer-first approach, we’re ready to deliver tubing that performs exactly how you need it to.

If you're interested in custom plastic extrusion for your business, reach out to us today for a personalised consultation and quote. Our team of experts is ready to assist you in bringing your plastic product ideas to life.