Bespoke & Standard Extruded Plastic Profiles

Co-Extruded Plastic Profiles | Rocal Extrusions

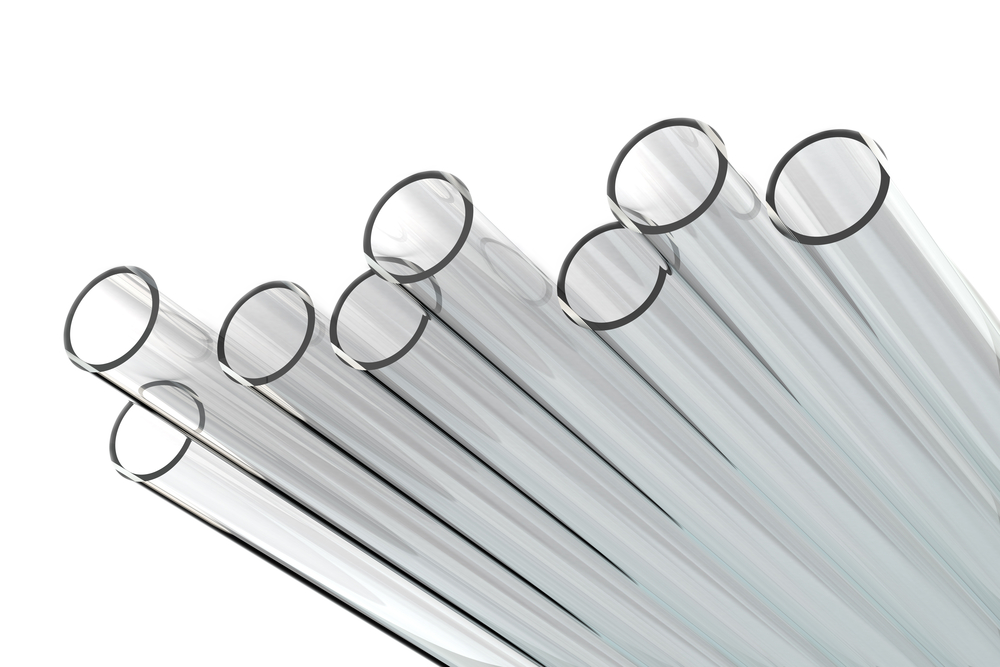

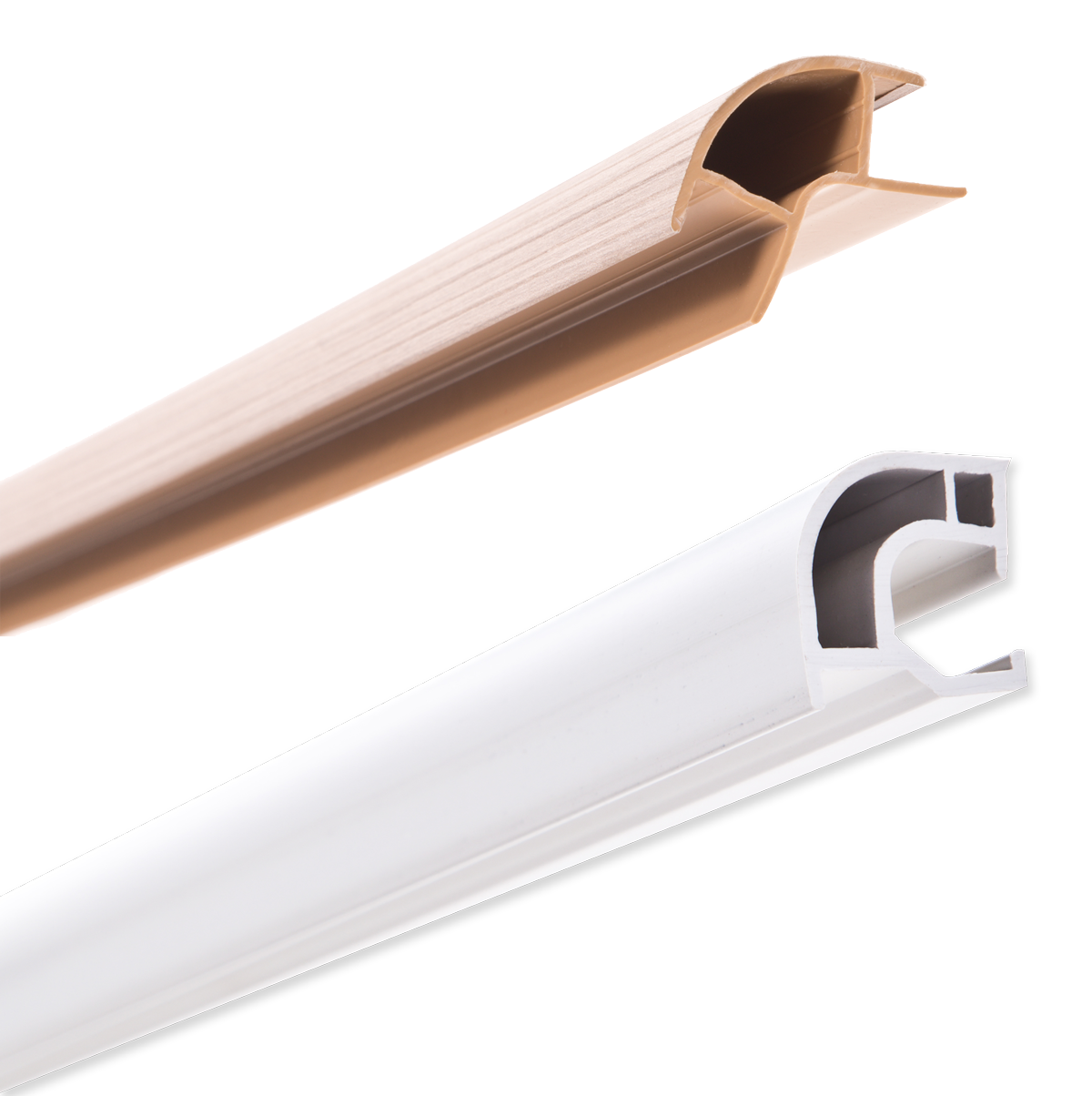

Rocal Extrusions specialise in the design and manufacture of co-extruded plastic profiles that combine multiple materials or textures within a single, seamless product. Through the co-extrusion process, we can create extruded plastic profiles that feature both rigid and flexible sections ideal for applications where performance, sealing, and durability are essential.

This innovative approach is often used as an alternative to adding a separate gasket or seal to a rigid plastic extrusion, saving both time and production costs.

Rocal Extrusions specialise in the design and manufacture of co-extruded plastic profiles that combine multiple materials or textures within a single, seamless product. Through the co-extrusion process, we can create extruded plastic profiles that feature both rigid and flexible sections ideal for applications where performance, sealing, and durability are essential.

This innovative approach is often used as an alternative to adding a separate gasket or seal to a rigid plastic extrusion, saving both time and production costs.

What is Co-Extrusion?

Co-extrusion is an advanced plastic extrusion process that uses multiple plastic profile extruders to produce complex, multi-material extruded plastic shapes. Each extruder feeds a different PVC or polymer blend, allowing rigid and flexible materials to be bonded together in a single step.

At Rocal Extrusions, our experienced team has developed countless co-extruded plastic profiles for a wide variety of industries and applications. We work closely with our customers to specify the right material combinations and manufacturing process to deliver durable, high-performance results.

Key Benefits of Co-Extruded Profiles

Excellent Sealing & Flexibility

Common uses for co-extruded plastic profiles include window seals, shower flippers, and joining strips for cladding. By carefully selecting and combining polymer blends, we can produce extruded plastic shapes that offer excellent sealing properties, flexibility, and resilience against compression and wear.

Weatherproof & Temperature-Resistant Design

Our extruded plastic profiles can be engineered for exceptional weatherability and temperature stability, remaining resistant to shrinkage or warping in both hot and cold conditions. This makes them ideal for outdoor and demanding industrial applications.

Efficient Manufacturing Process

The co-extrusion process is highly efficient, requiring minimal manual labour once the plastic profile extruders are set up and running. This eliminates the need for secondary operations to bond multiple polymer layers, ensuring consistent quality and reduced production time.

Cost-Effective Production

By combining two materials with different properties during the extrusion stage, co-extruded plastic profiles help reduce assembly costs and manufacturing time. This makes them one of the most economical and efficient plastic extrusion solutions available.

Co-Extruded Profiles Prices

The team at Rocal Extrusions are dedicated to providing the very best customer service as well as fast lead times for our customers. We make it easier than ever to find prices on our extrusion products. Contact us online to request a bespoke co extruded profile quote today!

Our Co-Extrusion Capabilities

Rocal Extrusions have extensive experience manufacturing complex co-extruded plastic profiles from multiple PVC and polymer materials. These are intricately bonded together to produce one seamless, high-performance extrusion.

Common configurations include:

- Combining rigid and flexible materials

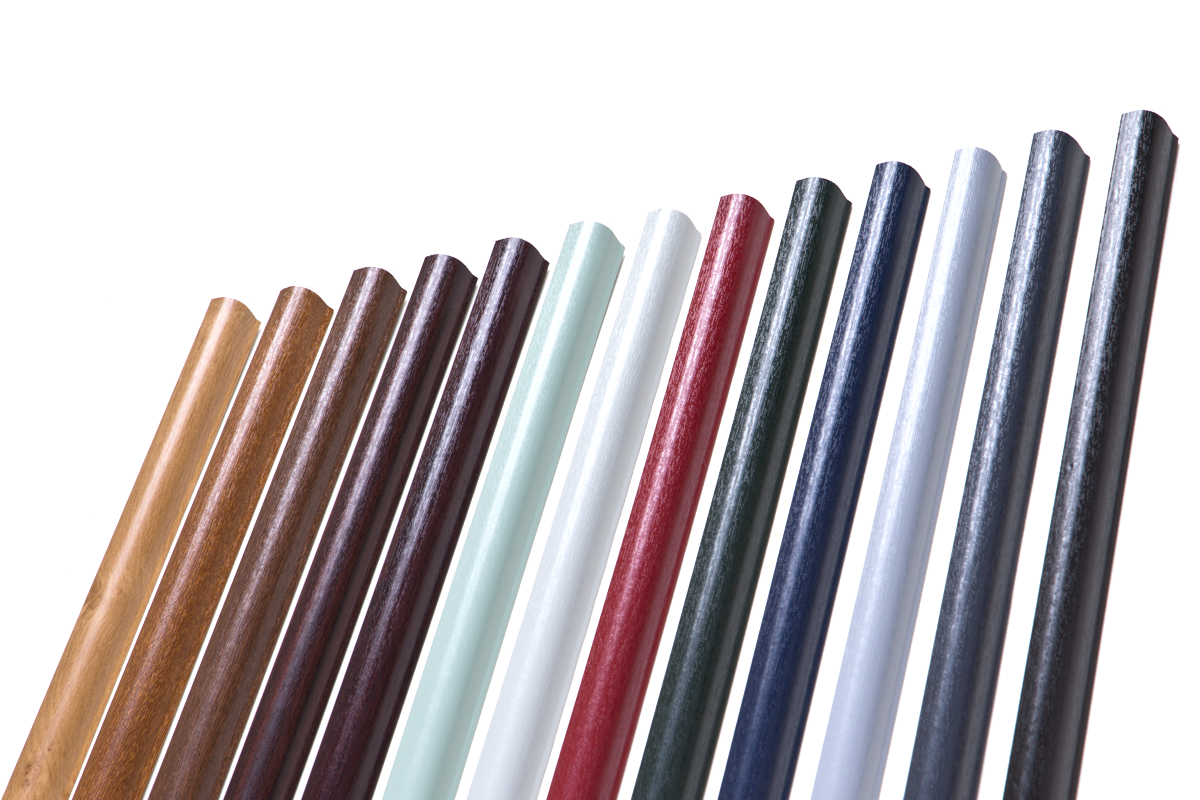

- Blending different coloured materials

- Joining two rigid materials using a flexible hinge

With our in-house tooling facilities and advanced plastic profile extruders, we can produce bespoke extruded plastic shapes quickly, cost-effectively, and with exceptional precision.

Cost-Efficient Bespoke Extruded Plastic Profile Development

Developing high-performance extruded plastic profiles can be a complex process but our in-house design team makes it straightforward. We can specify the material blend, tooling, and process parameters needed to produce your bespoke co-extruded plastic profiles efficiently and affordably.

Because Rocal Extrusions have full in-house tooling capabilities, we can design and adapt tooling without delay or external cost. This flexibility ensures faster turnaround times and optimised results for every project.

Contact us online to request a bespoke co-extruded plastic profile quote today.

How do we Manufacture

Co-extruded Plastic Extrusions?

Rather than using a single plastic extruder, co-extruded profiles utilise two or more plastic profile extruders, each fed with a different polymer blend. For example, one extruder may process a rigid polymer for structure, while another processes a flexible blend for sealing.

Each extruded plastic shape is formed as the materials combine in a single die, bonding together to create a strong, unified co-extruded plastic profile.

Once shaped, the profiles are cooled in a series of water baths to set their structure before being cut to size and prepared for distribution.

FAQs

Co-extruded plastic extrusions combine the perfomance benefits of both flexible and rigid plastic profiles by welding them together into one single, high performance extrusion. They are often used to weather seal properties.

Downloads

COMPANY

PRESENTATION

Promotional presentation for Rocal Extrusions with information about our company and services.

TIMBPLAS

PRESENTATION

Promotional presentation for the TimbPlas product including USPs and Case Studies.