FLEXIBLE

PLASTIC

EXTRUSIONS

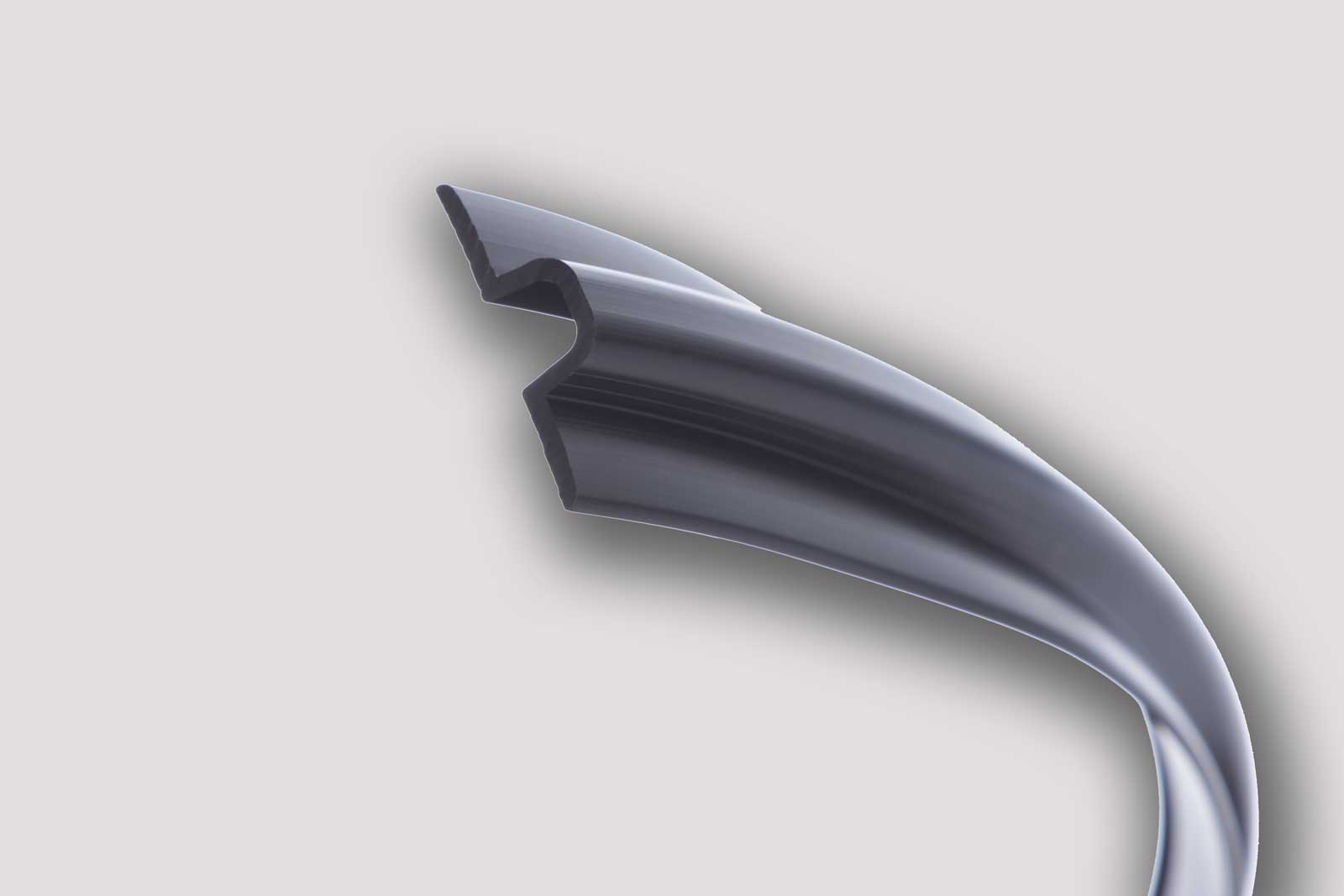

We manufacture flexible plastic extrusions in an impressive range of different profiles and materials.

Once we understand your desired application, our team can get to work developing and specifying the ideal blend of polymer to deliver a flexible plastic extrusion that perfectly meets your needs.

Depending on your application, we can extrude flexible plastic profiles using either PVC or LDPE.

We manufacture flexible plastic extrusions in an impressive range of different profiles and materials.

Once we understand your desired application, our team can get to work developing and specifying the ideal blend of polymer to deliver a flexible plastic extrusion that perfectly meets your needs.

Depending on your application, we can extrude flexible plastic profiles using either PVC or LDPE.

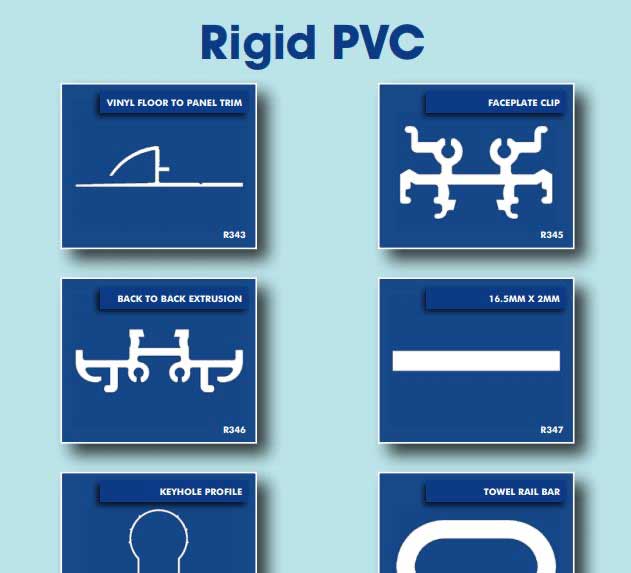

STANDARD

FLEXIBLE PLASTIC

EXTRUSIONS

Whilst we specialise in the development and delivery of bespoke flexible plastic extrusions, we also offer a small selection of standard flexible plastic profiles too.

With over a decade producing flexible plastic extrusions for a variety of different industries and applications, we may already have a flexible plastic profile that perfectly meets your requirements.

BESPOKE

FLEXIBLE

PLASTIC

EXTRUSIONS

If you are looking for a bespoke gasket, seal or flexible tube, our knowledgeable team can help develop a flexible plastic extrusions to fulfil your desired application.

Using our in-house tooling capability, Rocal Extrusions can develop and manufacture bespoke profiles without the need to outsource, meaning developing your bespoke extrusion can be done quickly and cost-effectively.

FLEXIBLE PLASTIC

EXTRUSION PRICES

By offering our own in-house tooling facility, Rocal Extrusions avoid the need for outsourcing costly work like developing brand new bespoke tools for custom profile development. By manufacturing our own tooling, we can not only pass on these cost savings to our customers but also refine and tweak our tooling to ensure consistent quality, every time.

To request a quote for one of our standard flexible plastic profiles, or a price for a bespoke requirement, use the link below.

FLEXIBLE PLASTIC EXTRUSION MATERIALS

At Rocal Extrusions we choose to manufacture our flexible plastic extrusions using either PVC or LDPE rather than rubber.

We choose to use these materials for several reasons, some of these are listed below:

RECYCLABLE

& ROBUST

Unlike rubber flexible plastic extrusions, when manufactured using PVC, flexible profiles can be re-ground and recycled to produce new plastic products.

PVC flexible plastic extrusions also offer far greater resistance to abrasion and offer superior insulating properties when compared to their rubber counterparts.

SIMPLE &

COST EFFECTIVE

Generally, extruding PVC or LDPE is a much simpler process than rubber as there is no vulcanising required.

This enables Rocal Extrusions to manufacture our flexible plastic extrusions more cost-effectively and to pass those savings on to our customers.

COLOUR

FLEXIBILITY

Whilst rubber flexible plastic extrusions are generally available in just the colour black, PVC and LDPE flexible profiles can be made in any colour, including clear.

This allows our customers a greater degree of flexibility when designing new products for our customers.

FLEXIBLE PLASTIC

EXTRUSION USES

Flexible plastic extrusions are used in a wide variety of different applications. Depending on the polymer mix used, Rocal Extrusions can produce flexible profiles that possess varying levels of rigidity to suit your desired use. Unlike rigid profiles, flexible plastic extrusions can be manufactured with irregular wall thicknesses, making them ideal for use in sealing systems or connecting components.

Typical uses for flexible plastic extrusions include:

• Window seals

• Curtain walling

• Seals and Gaskets

• Wire Management

• Weather seals

Downloads

COMPANY

PRESENTATION

Promotional presentation for Rocal Extrusions with information about our company and services.

TIMBPLAS

PRESENTATION

Promotional presentation for the TimbPlas product including USPs and Case Studies.