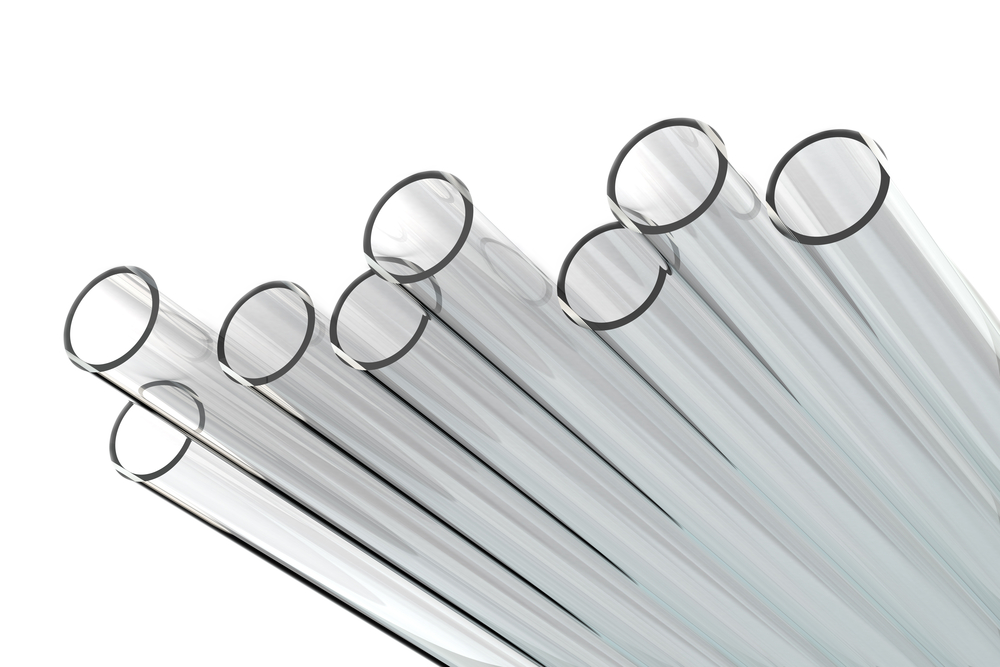

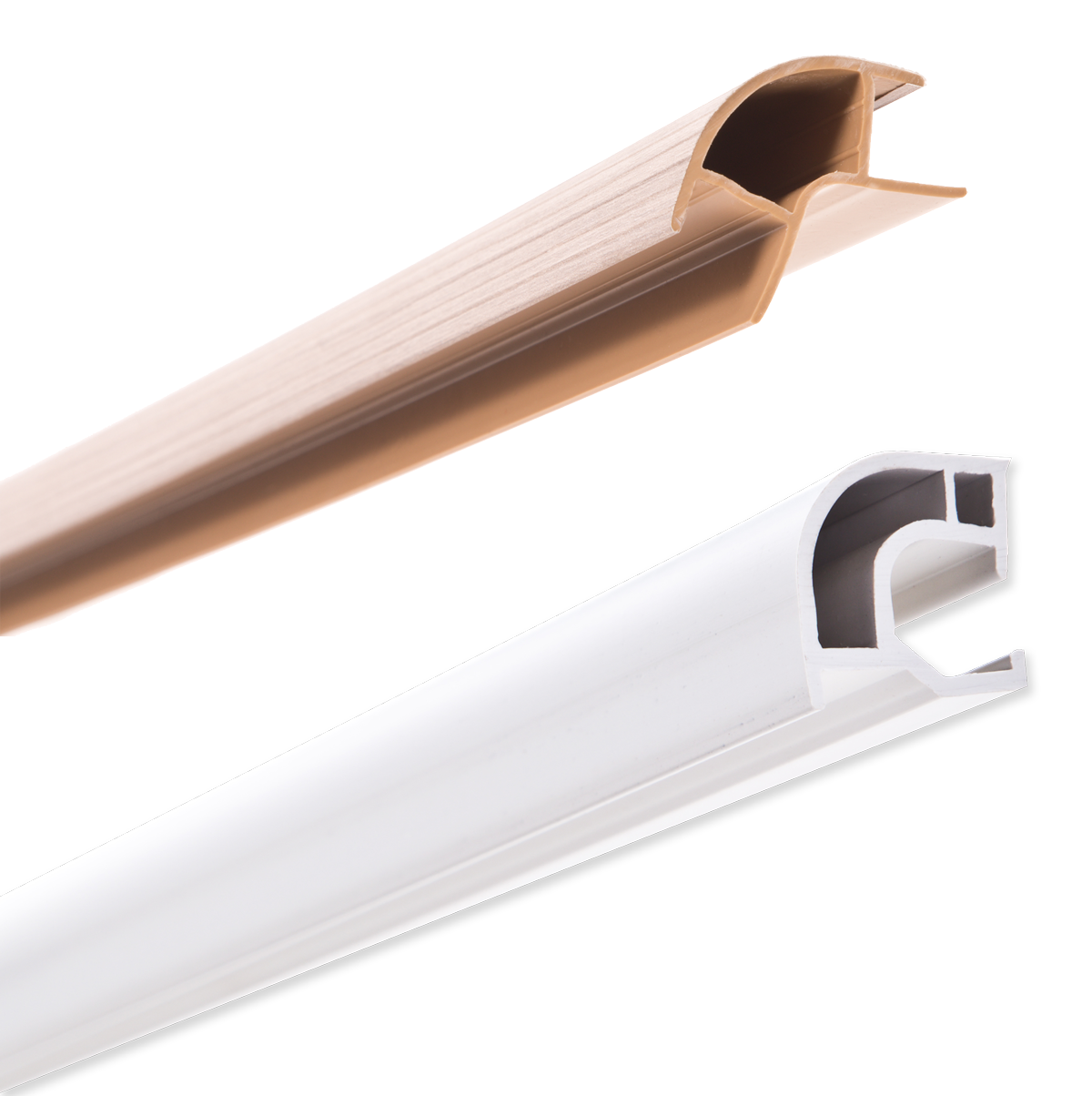

Co-Extruded Profiles

Co-extrusion is an extrusion process that is used to produce plastic profiles that combine two textures. This process is often used to create plastic extrusions that have a rigid structure but also have flexible sections too. Co-extrusion is commonly used in place of adding a gasket or seal to a rigid plastic profile as a secondary operation on assembly.

To create a co-extruded profile, compatible PVC materials that will bond together to form a robust finished product must be specified. Here at Rocal Extrusions, our experienced team have developed countless co-extruded profiles to perform a vast array of different purposes. With our expertise, we can help develop bespoke co-extruded profiles to perfectly meet your requirements.

Co-extrusion is an extrusion process that is used to produce plastic profiles that combine two textures. This process is often used to create plastic extrusions that have a rigid structure but also have flexible sections too. Co-extrusion is commonly used in place of adding a gasket or seal to a rigid plastic profile as a secondary operation on assembly.

To create a co-extruded profile, compatible PVC materials that will bond together to form a robust finished product must be specified. Here at Rocal Extrusions, our experienced team have developed countless co-extruded profiles to perform a vast array of different purposes. With our expertise, we can help develop bespoke co-extruded profiles to perfectly meet your requirements.

Key Benefits of Co-Extruded Profiles

Excellent Sealing Properties

Common uses of co-extruded profiles include window seals, shower flippers and joining strips for cladding. By carefully specifying a unique blend of materials, Rocal Extrusions can design a seal that best suits the conditions in which it will be installed.

Weatherproofed Design

Co-extruded profiles can also be developed to offer excellent weatherability and flexibility. Furthermore, co-extruded profiles can be made being resistant to any temperature related (hot or cold) shrinkage.

Straightforward Manufacturing Process

Co-extrusion is a simple process that requires only a minimal level of manual labour once the manufacturing equipment is set up and running. They don’t rely on a secondary operation to bond together two different polymer extrusions.

Cost Effective

Co-extruded profiles allow two materials with very different properties to be bonded together as part of the manufacturing process, saving additional labour and cost post manufacture.

Co-Extruded Profiles Prices

Rocal Extrusions are dedicated to providing customers with fast pricing turnarounds. Whether you’re looking for standard profiles or something custom, we’ll provide a bespoke quote that suits your project. Contact us online for extrusion prices today!

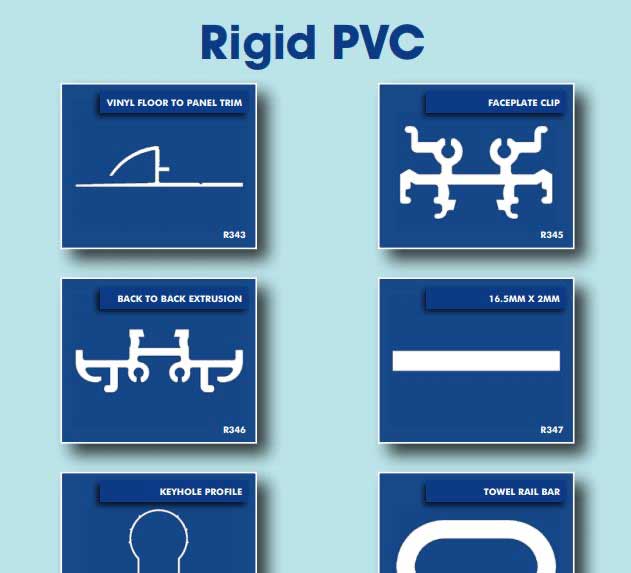

Our Co-Extrusion Capabilities

Rocal Extrusions have extensive experience developing complex co-extruded profiles that are comprised of multiple PVC materials that are intricately bonded together to produce one single seamless extrusion.

Our co-extrusion capabilities allow us to produce a wide array of co-extruded profiles that are uniquely specified to perform an individual purpose. Some of the more common co-extruded profiles we manufacture include:

- Combining of rigid and flexible materials

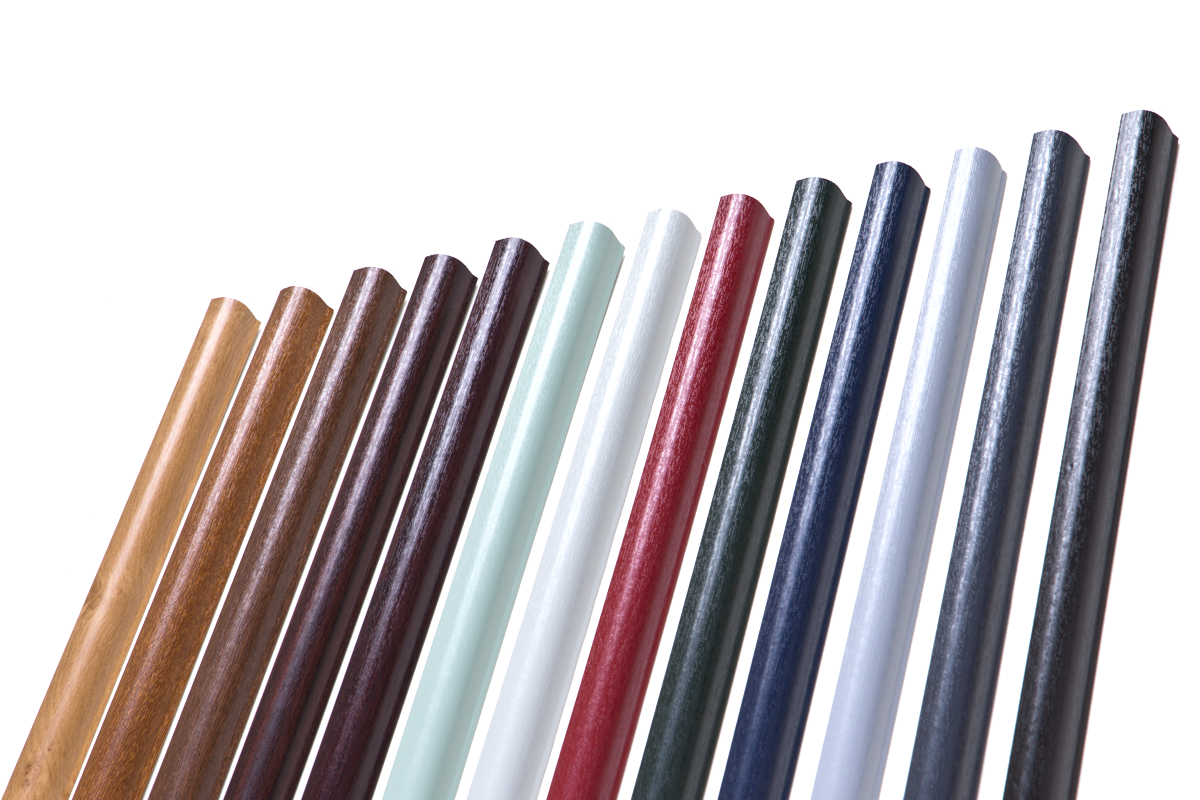

- Combining different coloured materials

- Joining two rigid materials using a flexible hinge

Co-Extruded Plastic Profile Prices

Despite the development of high performing co-extruded profiles being rather technical, our in-house design team can help specify a profile, material blend and manufacturing process that will allow Rocal Extrusions to produce bespoke co-extruded profiles for your requirements quickly and cost effectively.

As we also have our own in-house tooling facility, we can also produce bespoke tooling far more cost-effectively than other extruders, taking away from the development cost of bespoke co-extruded profiles. Throughout the development process, it may be necessary to make small changes and adaptions to our tooling to deliver a better quality product at a higher level of efficiency. Without having to rely on external toolmakers, we can make such changes without delay and without incurring additional cost.

To request a quote for a bespoke co-extruded profile, use the link below.

How do we Manufacture

Co-extruded Plastic Extrusions?

Rather than using a single extruder, co-extruded profiles utilise two extruders, each being fed with a different polymer blend that are combined to create the co-extruded profile. For example, one extruder may be fed with a rigid polymer blend and the other fed with flexible. When combined, this could create a plastic extrusion that offers a rigid structure but also a flexible gasket.

Each extruder is fed using a computer-controlled hopper, ensuring exactly the right amount of each polymer blend is fed into the extrusion machine. As the polymer is fed into the machine, it is drawn down and heated through the screw before being forced through a die to give it its shape. Each material is targeted through the relevant section of the die as the two become bonded together forming the co-extruded profiles.

The co-extruded profiles are then taken through a series of cold water baths to cool and set their shape before being cut to size and packaged for distribution.

Co-Extruded Profiles Prices

The team at Rocal Extrusions are dedicated to providing the very best customer service as well as fast lead times for our customers. We make it easier than ever to find prices on our extrusion products. Contact us online to request a bespoke co extruded profile quote today!

Downloads

COMPANY

PRESENTATION

Promotional presentation for Rocal Extrusions with information about our company and services.

TIMBPLAS

PRESENTATION

Promotional presentation for the TimbPlas product including USPs and Case Studies.